Packaging Analysis

Plastics packaging have a fundamental role to play in our everyday life. They preserve our food from contamination, they extend the food shelf life, they can increase resistance of our glasses, they protect our medicines and pharmaceuticals products, they can be manufactured to pack liquids, powder, and solids, they can be smart (for example to improve the food integrity and/or to guarantee food traceability), and much more. To ensure all these important functions, a single polymer material is not always enough; thus, plastics packaging becomes more and more complex and incorporates many different polymers and additives often combined in a multilayers structure, to provide all the properties needed.

��������ֱ�� Raman microscopy solutions and the LabSpec 6 software platform make it easy to obtain a full and complete characterization of all the polymers, additives in any packaging structure. Defect and failure analysis, reverse engineering, production support and research and development on new polymer materials: The ��������ֱ�� solution can help your analysis to reach your goals.

Nowadays, the plastic packaging industry is facing new challenges due to the increased global focus on the recyclability and sustainability targets in each product value chain, new materials (paper and cardboard packaging for example), and new formulations coming into the market. Indeed, product design is one of the key tools to improve packaging recycling, with these design improvements cutting in half the cost and the time of recycling plastic packaging waste.

Over the last 20 years, plastics food packaging has undergone several transformations to better preserve quality and extend the lifecycle of foods, but also to optimize production cost achieved through both the use of new polymer materials and from the optimization of the existing ones. These new and old polymer materials and additives have been combined to obtain complex multi-layered structures (which may have 10-15 layers or more, with an overall thickness ranging from few tens, up to several hundreds of microns), with the goal to improve the packaging properties and functionalities such as chemical barriers, mechanical/heat resistance, avoid bacteria contamination, etc.

Today, as mentioned, the new circular economy strategy is changing the main drivers for the packaging companies, now with the main goal being to design packaging that is recyclable, reusable or compostable and biodegradable.

Below are challenges to be addressed:

To support R&D and QC labs in their new challenges, ��������ֱ�� has developed a full solution:

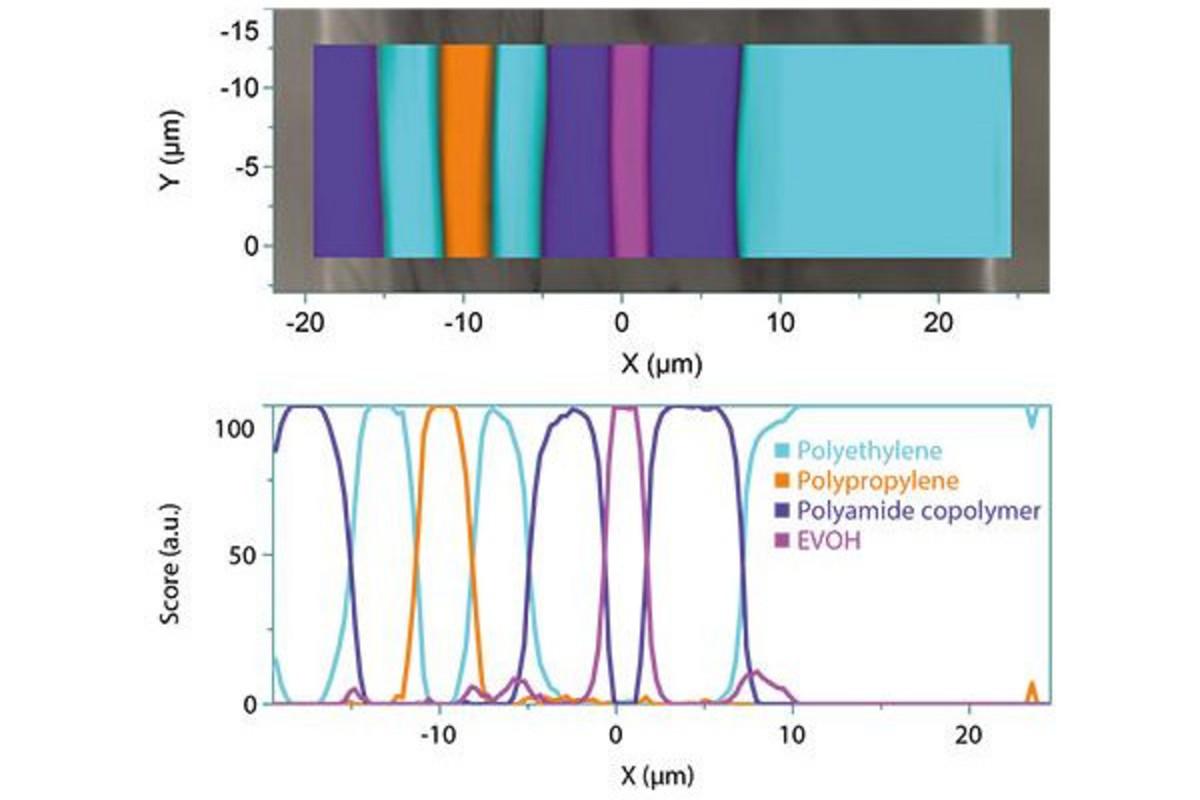

Raman microscopy, considering its capability to reach spatial resolution down to 1 micron and below, is the perfect tool to analyze complex packaging structures where layer thickness can be less than 1 micron, and it can address all the new challenges of the packaging industry. Some of its advantages are:

Choice of three Raman platforms

Affordable Benchtop Raman Spectrometer

Raman Spectrometer - Confocal Raman Microscope

Raman Microscope

Dedicated software and tools

Identify and differentiate polymer multilayers structure

Complete tool-kit allowing sample preparation to analyse in cross section multilayers structure

In this webinar, Massimiliano Rocchia and Ludivine Fromentoux, ��������ֱ�� Scientific, will demonstrate Raman microscopy solutions that enable scientists to obtain full and complete characterization data for all polymer films, from defect analysis to multilayer materials characterization.

In this webinar you will learn how the new Circular Economy Action Plan will influence the design of the future packaging and its waste management and you will gain insights how Raman Spectroscopy/Microscopy can be the perfect tool to address these new challenges.

Multilayer polymer films, composed of different materials, are used in a variety of industrial applications. The analysis of these multilayers is important to support the production, to identify defect and perform failure analysis, to understand delamination problem due to adhesion issue (lack or non-uniform distribution of the adhesive) and for reverse engineering investigation.

У вас есть вопросы или пожелания? Используйте эту форму, чтобы связаться с нашими специалистами.